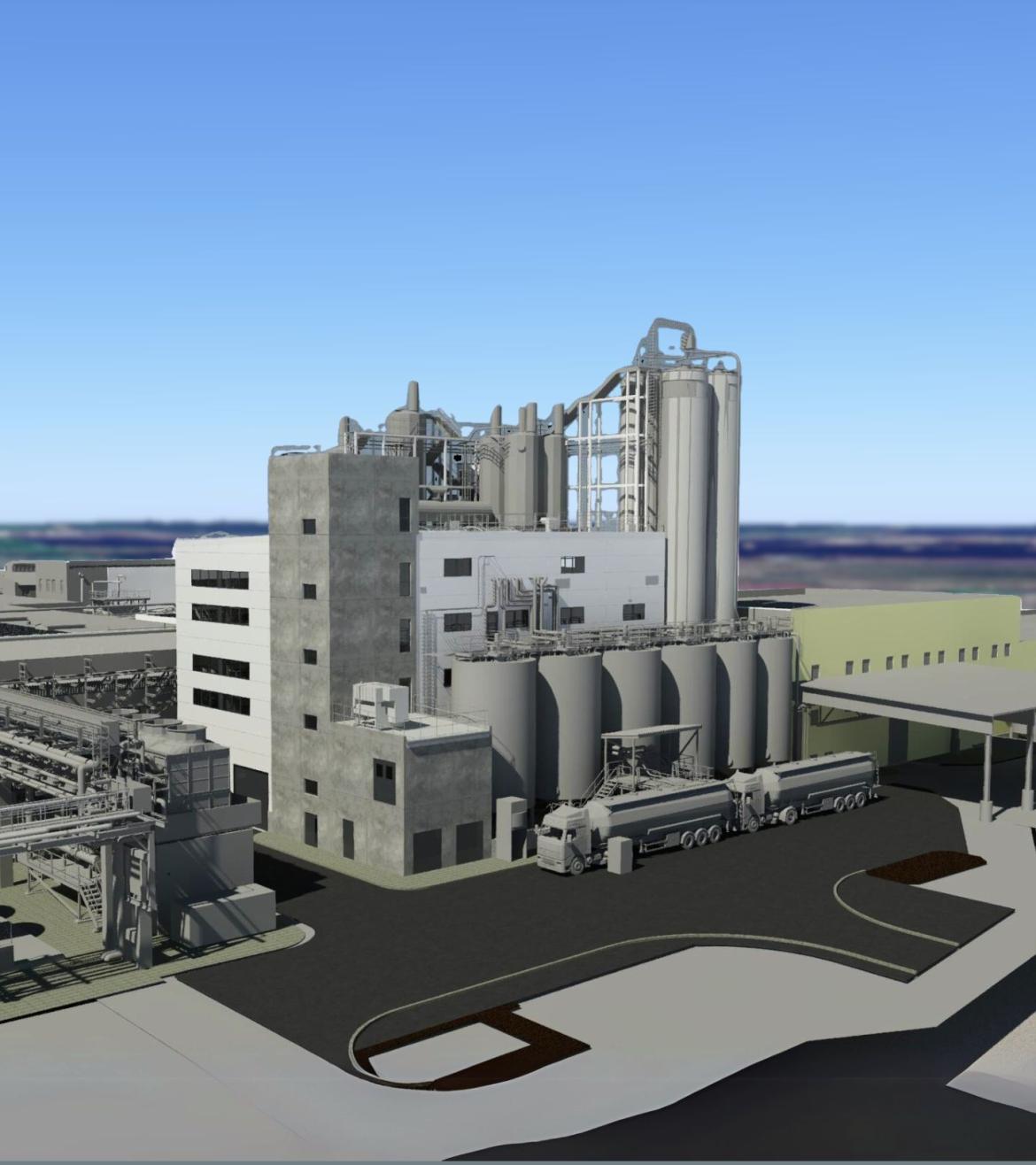

The concern "Latvijas Finieris Group", in collaboration with research institutions and scientists, is developing a new synthetic resin production process based on the natural wood component lignin. This approach will allow reducing the use of fossil raw materials in phenol formaldehyde resins, which are used in the production of furniture, flooring, thermal insulation, sandpaper and other everyday products. The Group has already started construction of a new factory in Riga, Bolderāja, to implement this innovative project.

The event was complemented by the seminar "Research, Industry, Innovations – Stories of Synergy", where experience was shared by the Latvian State Institute of Wood Chemistry, leading researcher Jānis Rižikovs; the Latvian State Forest Research Institute "Silava", leading researcher Andis Lazdiņš; and Māris Būmanis, Member of the Board at the "Latvijas Finieris".

The factory construction is part of the international research consortium project “VIOBOND”, led by "Latvijas Finieris", which unites eight partners from five EU member states. The project aims to develop a formula and create the world’s first industrial production technology for "greener," more environmentally and human-friendly synthetic phenol-formaldehyde resins currently used in plywood, insulation materials, furniture, flooring, sandpaper, and many other everyday products.

The total research costs for the VIOBOND project amount to €32 million, of which €16 million comes from the European Commission's Horizon 2020 research and innovation funding program, with the remainder contributed by the participating companies.

To implement the project, "Latvijas Finieris" will conduct research worth €16 million, with €8 million co-financed by the "Horizon Europe" program. The total investment by "Latvijas Finieris" for constructing the factory is approximately €40 million.

The grant agreement signing process was completed on May 18, 2021, officially marking the beginning of this significant collaboration. The project is scheduled for completion by August 31, 2027, with factory construction expected to be finalized by the spring of 2026.